Products

KOREA HEAT TREATMENT

Customer

Service

02-2270-9486

FAX : 02-2270-9661

HOME > Products > Deformed PC Steel Bar > Concrete pile and steel wire for telegraph pole (ULBON)

Concrete pile and steel wire for telegraph pole (ULBON)

Aplication

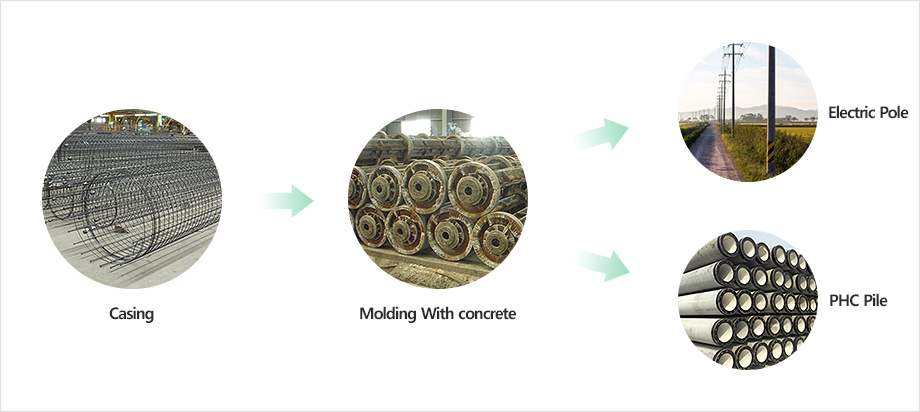

The high tension release PC steel rod used for the prestress concretepile by the pretension mode applying the centrifugal force and makes and electric pole

Product feature

| Item | Content |

|---|---|

| Superior Yield Ratio | The yield ratio of 90% or more is maintained. The concrete quality is improved in use |

| Low Relaxation | Relaxation Loss, the stress loss value, is extremely small for a long time (1,000 hours) less than 2.5% |

| Excellent adhesion | The separate fixing equipment unnecessary.It has the strong adhesive force with the concrete with the uniform spiral groove of 3~6 in the product surface |

| Excellent spot weldability | The mechanical property of product due to the Spot welding is not degraded in the automatic knitting machine use, so it a lot contributes to the quality upgrading of the concrete product and productivity improvement through automation |

| Excellent Straightness | The separate correction work is unnecessary the straightness of the winding former is restored in use it loosens in the Coil state of product. |

| Uniform cross section | The uniform cross sectional area is maintained and the cross section history is uniform. The degradation of the mechanical property is not even if the head processing or the head operation is done |

Product species(KS D3505)

| Sort | Symbol | Title Diameter (mm) |

Standard diameter (mm) |

Tolerance | Nominal cross section (mm2) |

Unit weight (kg/m) |

|---|---|---|---|---|---|---|

| D Species 1 | SBPD 1275/1420 | 5.1 | 5.10 | ±0.05 | 19.6 | 0.154 |

| 6.1 | 6.10 | 28.3 | 0.222 | |||

| 7.4 | 7.25 | 40.0 | 0.314 | |||

| 8.3 | 8.33 | 52.5 | 0.412 | |||

| 9.2 | 9.25 | 64.0 | 0.503 | |||

| 10.0 | 10.38 | 78.5 | 0.617 | |||

| 11.0 | 11.10 | 90.0 | 0.707 | |||

| 11.2 | 11.53 | 100.0 | 0.786 | |||

| 13.0 | 13.10 | 125.0 | 0.983 | |||

| C Species 1 | SBPD 1080/1230 | 5.0 | 5.00 | ±0.05 | 18.1 | 0.142 |

| 7.0 | 7.00 | 35.4 | 0.204 | |||

| 8.0 | 8.00 | 46.3 | 0.278 | |||

| 9.0 | 9.00 | 58.5 | 0.363 | |||

| 11.0 | 11.00 | 87.4 | 0.686 | |||

| 13.0 | 13.00 | 122.1 | 0.959 |

Mechanical property

| Sort | Symbol | Yield strength (N/mm2) |

Tensile strength (N/mm2) |

elongation percentage (%) |

Relaxation (%)(T/S x 70%) |

|

|---|---|---|---|---|---|---|

| Room Temperature, 1,000Hr | ||||||

| D Species 1 | SBPD 1275/1420 | 1275(min) | 1420(min) | 7(min) | 2.5(Max) | |

| C Species 1 | SBPD 1080/1230 | 1080(min) | 1230(min) | 5(min) | ||

Chemical component

(Unit : %)

| P | S | Cu |

|---|---|---|

| 0.03(Max) | 0.035(Max) | 0.30 |

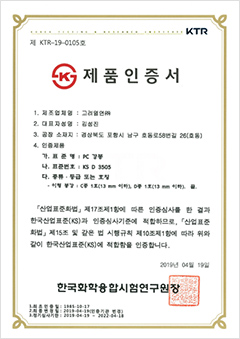

Authentication Information (KS Certification)

| Certification Number | Manu-facturer | Standard Name | Standard Number | Rank | Title | Initial permission |

|---|---|---|---|---|---|---|

| KTR-19-0105 | Korea Heat Treatment Co., Ltd | PC Steel Bar | KS D3505 | C Species 1, D Species 1 |

13.0mm (Max) | 85.10.17 |